For most of modern industrial history, we have been focused on making things faster, cheaper, and better. Innovation raced ahead from steam to silicon, from manual labor to automation, relentlessly pushing down the cost of production. Technological advancement allowed us to extract, refine, and transport resources with astonishing efficiency. Manufacturing bottlenecks were solved. Global supply chains scaled. Products became more accessible than ever.

But something subtle and profound is changing.

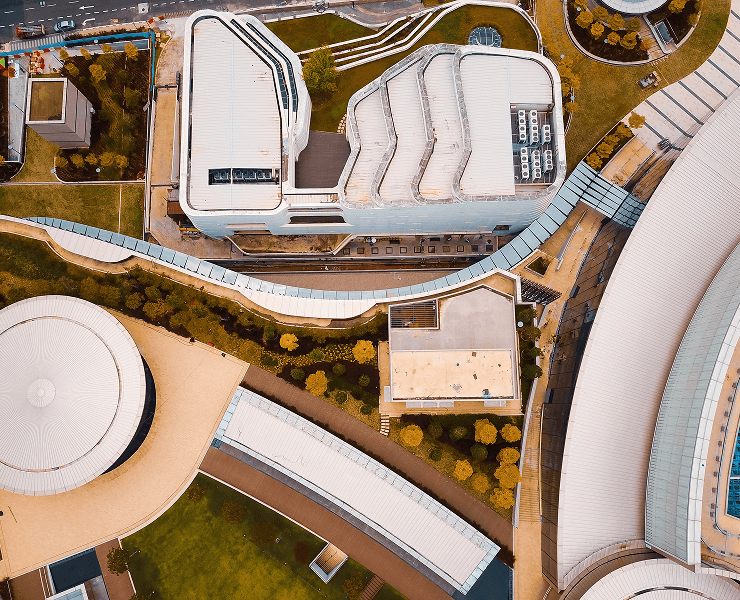

We are now reaching the edge of what efficiency alone can deliver. Many systems, from mining to energy to consumer goods, have already been optimized. Gains are becoming marginal focusing of number of units sold as opposed to margin from each unit. Meanwhile, global demand continues to rise, not just in volume, but in complexity and expectation. Billions of people are stepping into new levels of prosperity, with every additional step requiring more energy, more materials, more infrastructure.

And so the bottleneck has moved.

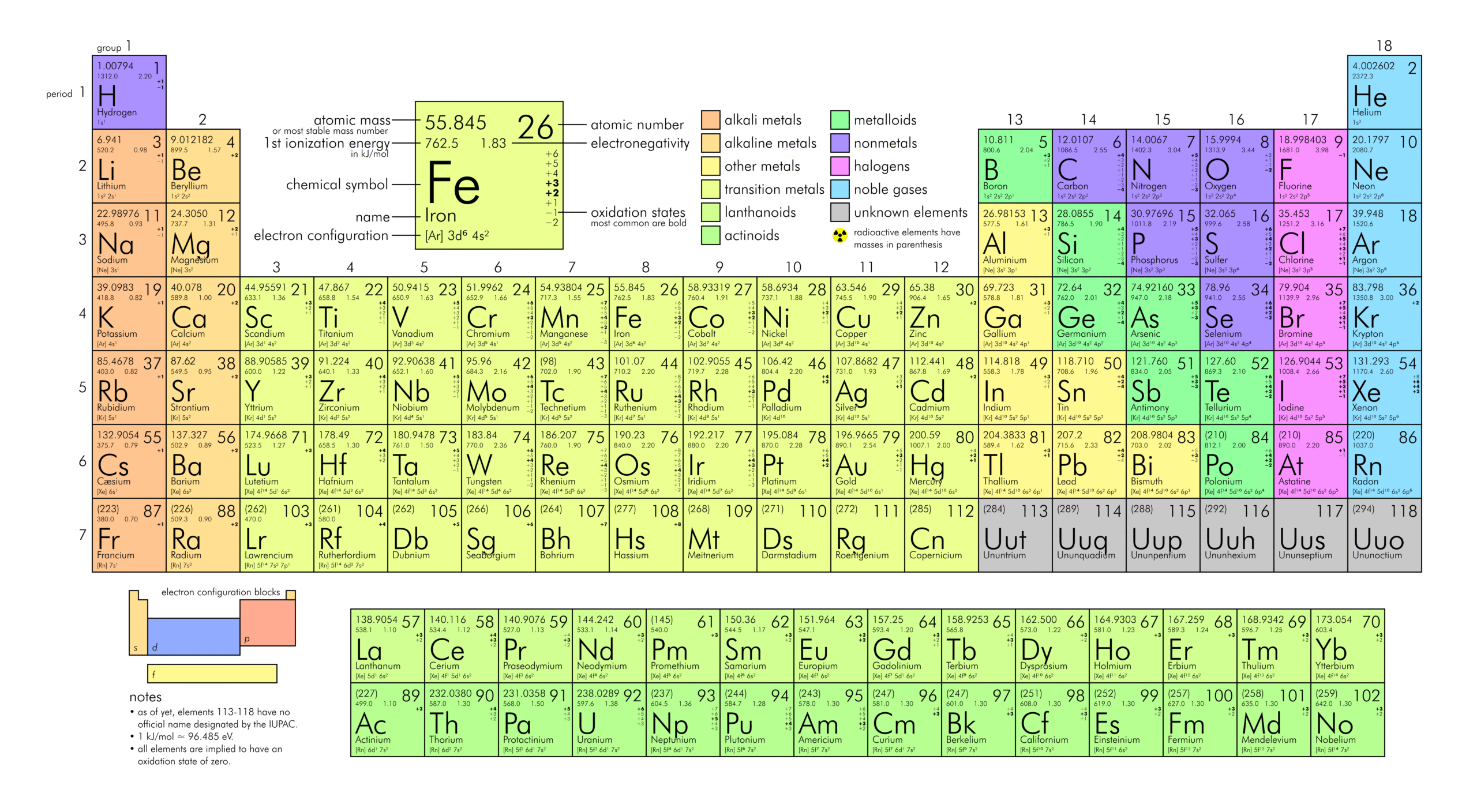

Today, it is no longer only the factories or the workflows that constrain us. It is the raw materials themselves. The earth beneath our feet. The lithium in our batteries, the copper in our grids, the rare earths in our technologies.

In a world of optimized systems and surging demand, the value has shifted upstream. Materials have become the new frontier of influence, not just economically, but geopolitically and ethically. The question is no longer “How do we build faster?” but “How do we secure what we need to build at all?”

This shift forces us to reconsider the foundations of progress. It calls for strategic response on three fronts:

Design for Less: We must build smarter, not just stronger. Engineering solutions that use less material to achieve more function. Dematerialization. Modularity. Products designed to be lighter, longer-lasting, and easier to disassemble. Efficiency not just in process, but in matter.

Commit to Circularity; The most ethical mine may not be in the ground it may be in yesterday’s product. Recycling is not just about sustainability; it is about sovereignty. Building closed-loop systems that recover and repurpose materials gives us resilience in a world of finite supply.

Finding Better Alternatives: Replacing scarce or environmentally damaging materials with more abundant, affordable, and sustainable substitutes is one of the most powerful ways to unlock long-term resilience. It takes science. It takes engineering. But from bio-based polymers to battery chemistries that reduce reliance on cobalt, the innovation is already happening.

Look Beyond Earth: It may sound distant, but the logic is simple: if our ambitions are planetary or even interplanetary, our resource base must expand accordingly. The conversation around space is no longer just about exploration. It is about preparation. If not today, then tomorrow, we will look outward for what is becoming scarce inward.

At Engina, we do not just observe these shifts, we work within them. With clients in mining, energy, advanced materials, and sustainability, we see how raw material access is shaping everything from innovation cycles to national strategies. But we also see the people behind these challenges: engineers trying to reduce cobalt intensity, policy makers navigating resource diplomacy, Indigenous leaders protecting the land they have stewarded for generations.

Will we compete for scarcity or collaborate for abundance?

Will we extract without end or redesign what is possible?

Will we treat materials as mere inputs or as shared responsibilities?

As always, the future will be engineered. But the question that defines us is not just what we can make, it is what we value.

Let’s make that the real measure of progress.