Engina Advances Breakthrough Rare Earth Extraction Technology with Avalon

November 24, 2025 — Toronto, ON Hybrid Supercritical Refining (HSR) demonstrates >90% rare-earth recoveries in preliminary assessment Engina Corporation is pleased to

At Engina Corporation, we help clients across the energy, mining, metals, and advanced materials sectors achieve smarter, more sustainable operations. Our case studies highlight how our engineering consulting services — from process design and technoeconomic analysis to sustainability solutions and energy transition strategies — drive measurable results.

Explore how we turn complex challenges into innovative solutions that create long-term value for communities, industries, and the environment.

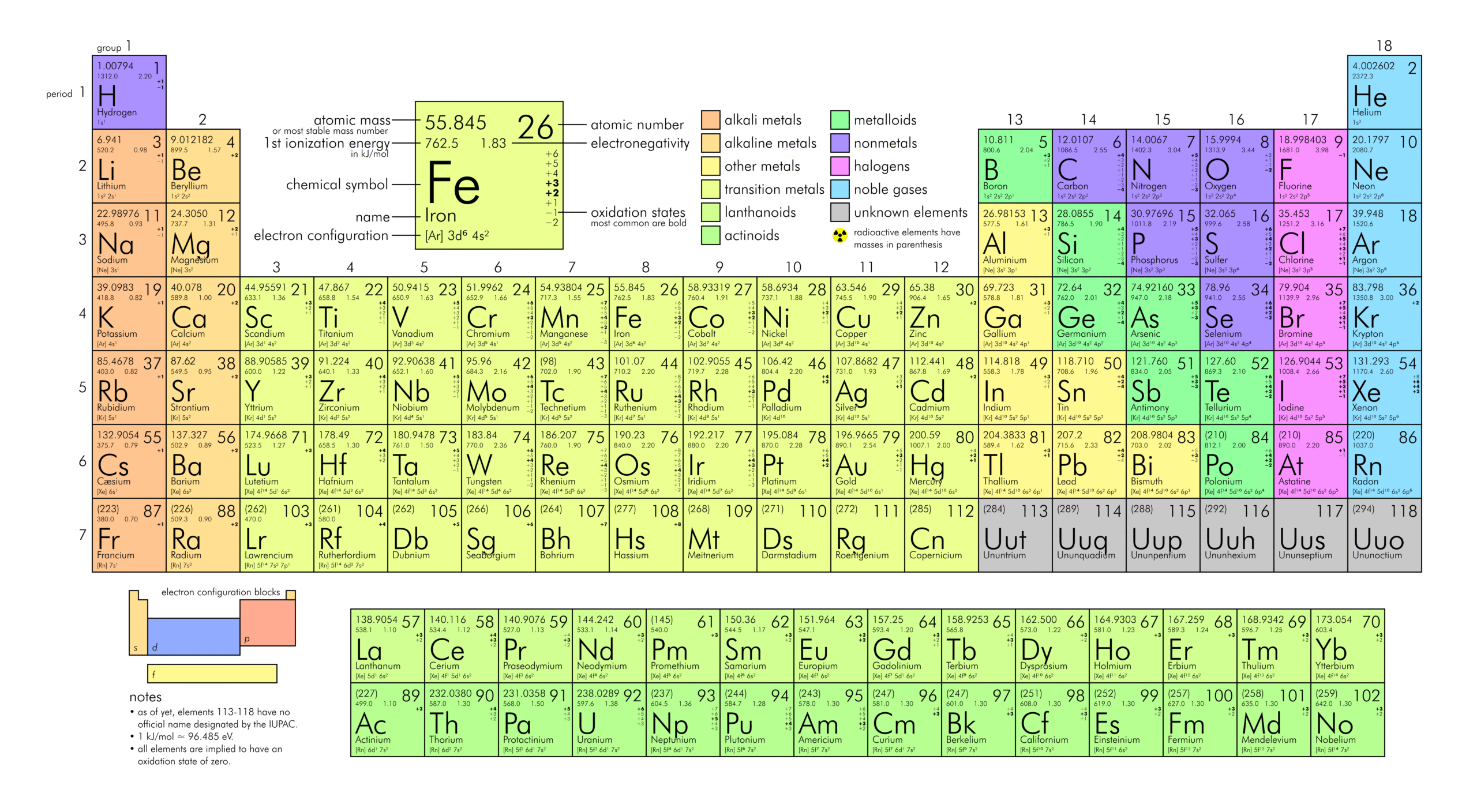

A government research agency engaged our team to perform a process simulation and technoeconomic analysis (TEA) of the magnet recycling flowsheet using hydrometallurgical processing and electrodialysis (ED)-based separation technology for recovering Neodymium (Nd) and Praseodymium (Pr). The project aimed to benchmark this method against traditional solvent extraction (SX) processes and support sustainable rare earth magnet manufacturing.

A federal research organization engaged us to develop a robust mathematical model based on physical and chemical behaviour of an electrochemical system to simulate the separation of rare earth elements (REEs) using electrodialysis-assisted solvent extraction. The goal was to optimize the process performance and to predict the purity and yield of critical REEs, specifically Neodymium (Nd),

A South American-Canadian resource development company engaged our consulting engineering firm to support its efforts in extracting rare earth elements (REEs) from ionic clay deposits in South America. The objective was to develop a technically viable and environmentally responsible process for REE recovery from these clay-hosted ores.

Our consulting engineering firm was engaged by a United States-based company to support the development of an innovative leaching technology for nickel and cobalt extraction from limonitic and saprolitic ores.

Our consulting engineering firm was engaged by a Canadian company seeking to improve the efficiency of its rare earth element (REE) recovery process from recycled REE ores. The client’s pregnant leach solution (PLS) contained a high concentration of Yttrium (Y)

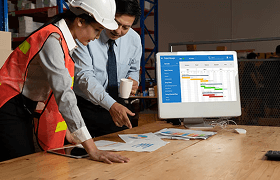

A European developer and owner of solar projects required a robust performance analytics platform to monitor, validate, and compare real-time plant generation data against forecasted and satellite-derived benchmarks. The goal was to streamline operational reporting, verify generation anomalies, and support data-driven asset management.

A renewable energy developer required a custom-built technoeconomic model to evaluate hybrid power systems incorporating solar photovoltaic (PV), battery energy storage (ES), micro hydro, diesel generators, with and without grid interaction. The tool needed to support project-level design, performance simulation, scheduling, and financial analysis to optimize the cost and renewable energy penetration.

A North American developer client engaged us to provide ongoing consulting and advisory services for the development of utility-scale power generation and storage assets tailored to support large-scale data centre operations. Our role spans from early-stage siting, to basic engineering, to detailed financial and performance modeling.

A global consulting client commissioned a comprehensive energy balance assessment for an integrated steelmaking facility under three distinct technology pathways: Submerged Arc Furnace (SAF), Basic Oxygen Furnace (BOF), and Electric Arc Furnace (EAF). The study aimed to identify optimal energy recovery strategies to reduce fossil fuel dependency and operating costs while informing future CAPEX decisions.

A US-based clean tech innovator sought alternatives to conventional amine-based carbon dioxide (CO₂) removal methods in natural gas processing. The objective was to evaluate the technoeconomic feasibility of a new solid sorbent-based technology developed in-house, with potential to improve efficiency and reduce environmental impact.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Based On 1300+ Reviews

November 24, 2025 — Toronto, ON Hybrid Supercritical Refining (HSR) demonstrates >90% rare-earth recoveries in preliminary assessment Engina Corporation is pleased to

For most of modern industrial history, we have been focused on making things faster, cheaper, and better. Innovation raced ahead from steam to

We do not often think about the materials that power our lives. But beneath the surface, sometimes quite literally, there is a growing

We welcome the opportunity to discuss your engineering challenges and explore how ENGINA CORPORATION’s consulting services can support your goals in mining, critical materials, energy transition, and clean technology. Let’s start the conversation.