Project Summary

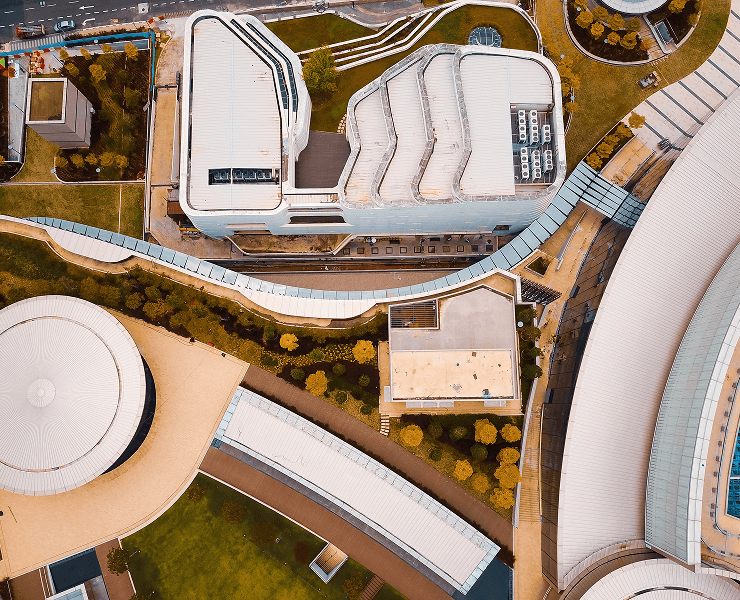

A global consulting client commissioned a comprehensive energy balance assessment for an integrated steelmaking facility under three distinct technology pathways: Submerged Arc Furnace (SAF), Basic Oxygen Furnace (BOF), and Electric Arc Furnace (EAF). The study aimed to identify optimal energy recovery strategies to reduce fossil fuel dependency and operating costs while informing future CAPEX decisions.

Challenge

Steel plants are among the most energy-intensive industrial operations, with complex thermal, chemical, and electrical flows. The client needed a strategic analysis to:

- Quantify energy flows for each processing route

- Evaluate flue gas heat recovery potential

- Optimize utility configurations

- Compare operating and capital trade-offs for each technology under nominal and reduced production scenarios

Solution

An in-depth energy balance model was developed for each of the three process cases (SAF, BOF, EAF), considering:

An in-depth energy balance model was developed for each of the three process cases (SAF, BOF, EAF), considering:

- Thermal, chemical, and electrical energy flows across units (e.g., coke oven, blast furnace, EAF, casting and rolling)

- High-level CAPEX estimates for heat recovery systems

- Comparative scenarios: full (Nominal) vs. minimal (Minimum) product output

Each configuration included:

- Flue gas recovery calculations

- Energy allocation diagrams (to scale)

- Steam and power co-generation scenarios

- Sensitivity to imported fossil fuels vs. domestic coal or syngas

Key Results

BOF Case:

Highest energy self-sufficiency via flue gas recovery

Avoids imported fuel and power but demands high CAPEX for recovery systems

SAF Case:

Recovers ~45% of thermal demand for casting/rolling from flue gas

Remaining demand met with fossil fuels

EAF Case:

Most electricity-intensive; uses scrap feed

Flue gas recovery offsets ~44% of downstream thermal needs

Flexible design allows thermal integration or scrap pre-heating

Business Impact

The client used the findings to:

- Prioritize CAPEX investments in energy recovery

- Compare fossil fuel reliance across technology pathways

- Enhance long-term operational economics through energy efficiency planning

This strategic modeling enabled data-driven decision-making for technology selection, project phasing, and energy procurement strategy in alignment with sustainability goals.

Trusted by Industry Leaders

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Based On 1300+ Reviews

Let’s Talk Solutions

We welcome the opportunity to discuss your engineering challenges and explore how ENGINA CORPORATION’s consulting services can support your goals in mining, critical materials, energy transition, and clean technology. Let’s start the conversation.